Din Rail Meaning: A Comprehensive Guide to Types and Uses

Table of Contents

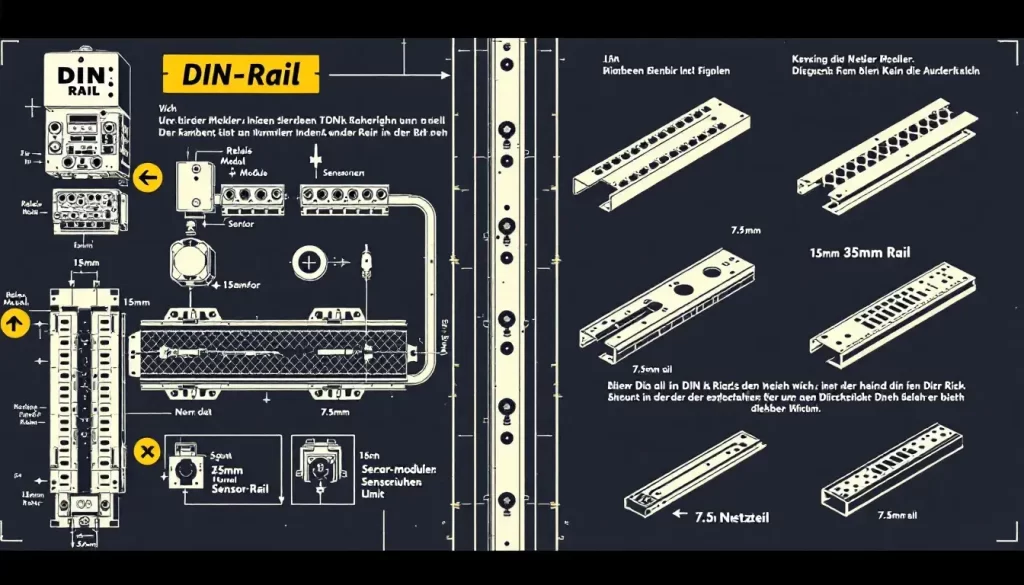

ToggleA DIN rail, which has a specific DIN rail meaning, is a metal bar used to mount electrical components. Created by the German Institute for Standardization (DIN), it helps organize and secure devices like circuit breakers. This guide covers types, uses, and why they are essential for electrical setups.

Key Takeaways

- DIN rails are standardized metal rails used to mount electrical components, providing organizational and structural benefits in various installations.

- There are multiple types of DIN rails, including TS35, TS15, C-Rails, and G-Rails, each designed for specific applications and load requirements.

- Adhering to international standards such as IEC and EN ensures the safety, reliability, and efficiency of DIN rail installations across different industries.

Understanding DIN Rail

What is DIN Rail?

A DIN rail is a standard type of metal rail used to mount electrical components like circuit breakers and terminal blocks. It was developed by the German Institute for Standardization, known as DIN, to provide a universal mounting solution. These rails are typically made from cold-rolled carbon steel or aluminum, offering durability and strength.

Key Features:

- Standard Size: The most common DIN rail size is 35mm wide, with heights of either 7.5mm or 15mm. This size is often referred to as the “Top Hat” rail due to its shape.

- Material: DIN rails are usually constructed from metal, such as steel or aluminum, which ensures they are robust and long-lasting.

- Applications: They are widely used in electrical installations, including control panels, switchgear, and industrial automation. DIN rails help organize and secure devices, making them easily accessible for maintenance.

Why Are They Important?

DIN rails play a crucial role in electrical setups by providing a standardized way to mount various components. This ensures that installations are organized, efficient, and safe. The standard dimensions allow for easy integration of components from different manufacturers, which is essential for flexibility and compatibility in electrical engineering.

Benefits:

- Organization: Helps keep electrical components neatly arranged.

- Efficiency: Simplifies the installation and maintenance process.

- Safety: Ensures secure mounting of components, reducing the risk of electrical faults.

By understanding the purpose and benefits of DIN rails, professionals can enhance the performance and reliability of their electrical installations.

Types of DIN Rails

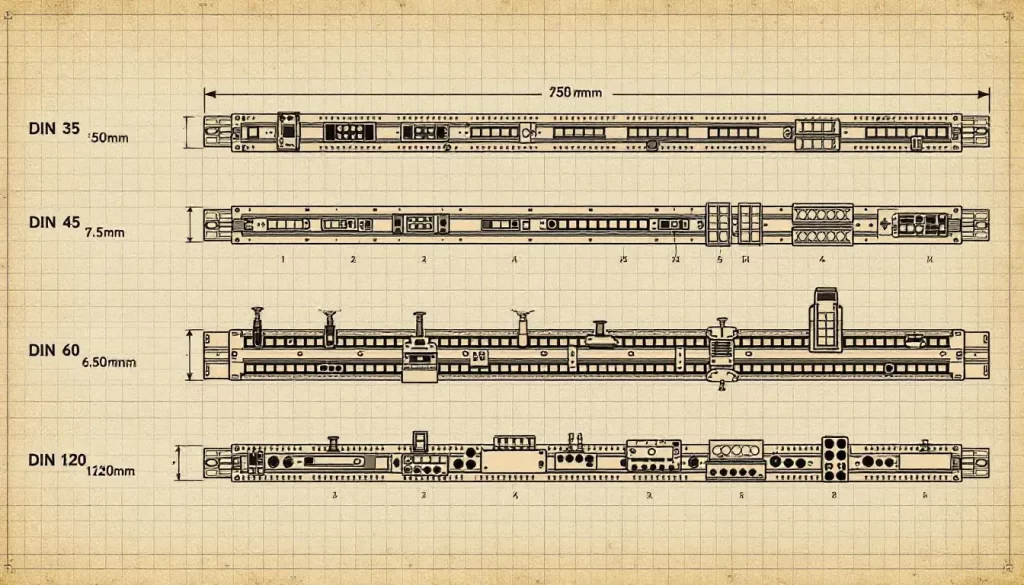

DIN rails come in different types, each serving specific needs. Here’s a straightforward breakdown:

1. Top Hat Rails (TS35)

- Size: Standard width of 35mm.

- Use: Most common type, used in industrial projects.

- Features: Known for versatility and adaptability.

- Applications: Ideal for control panels and industrial automation.

2. Mini Top Hat Rails (TS15)

- Size: 15mm wide, 5.5mm deep.

- Use: Perfect for tight spaces.

- Features: Strong despite compact size.

- Applications: Suitable for smaller electrical components.

3. C-Rails

- Size: Varies to support heavier loads.

- Use: Designed for heavy components like transformers.

- Features: Robust construction.

- Applications: Excellent for power supplies.

4. G-Rails

- Size: Deeper cavity for extra support.

- Use: Best for heavy machinery.

- Features: Provides strong alignment.

- Applications: Common in industrial settings.

Each type of DIN rail is made from durable materials like cold-rolled carbon steel, ensuring they last long and support electrical components securely. Understanding these types helps you choose the right rail for your

Applications of DIN Rails

DIN rails are incredibly versatile and find applications in various fields. Here’s a simplified look at where and how they are used:

Control Panels and Switchgear

- Purpose: DIN rails help organize electrical components like circuit breakers and contactor units.

- Benefit: They ensure a neat and efficient layout, making maintenance easier.

- Details: In control panels, DIN rails allow for easy mounting and servicing of terminal blocks and relays, boosting overall efficiency.

Industrial Automation

- Purpose: They support devices such as programmable logic controllers (PLCs) and motor controllers.

- Benefit: Provide a stable base for controllers and relays, improving system reliability.

- Details: In manufacturing settings, DIN rails help organize complex wiring, making installations cleaner and safer.

Consumer Electronics

- Purpose: Used for mounting smaller devices in enclosed spaces.

- Benefit: Enhance organization and efficiency in electrical setups.

- Details: Manufacturers use DIN rails to simplify the integration of components, streamlining assembly and maintenance.

Key Numbers

- Standard Width: The most common DIN rail width is 35mm, known as the “Top Hat” rail.

- Material Durability: Typically made from cold-rolled carbon steel or aluminum, ensuring long-lasting performance.

By understanding these applications, professionals can effectively utilize DIN rails to enhance the performance and reliability of electrical systems.

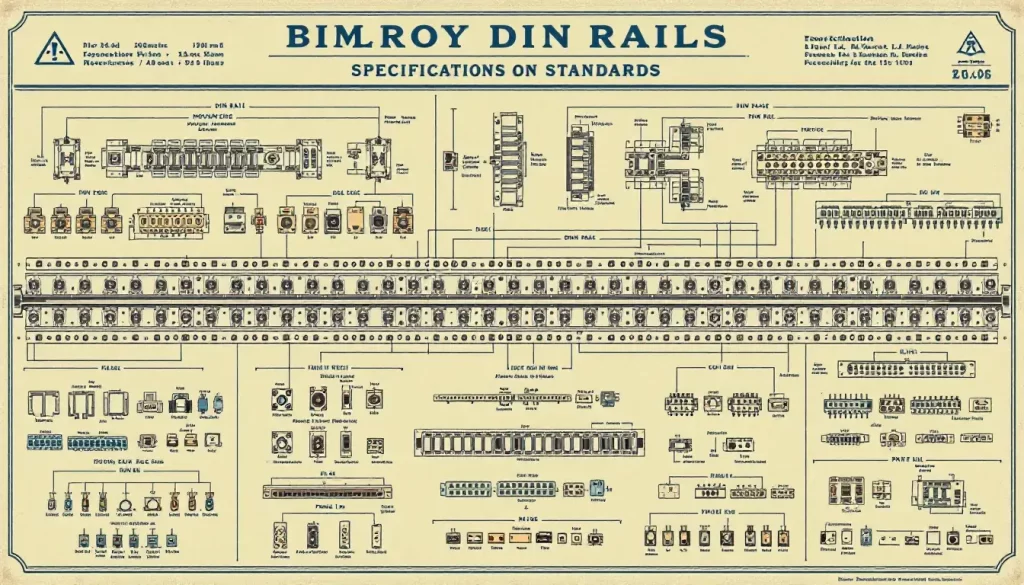

Specifications and Standards

- Standard Sizes: DIN rails are typically 35mm wide, with heights of 7.5mm or 15mm.

- Material: Modern DIN rails are made from metals like steel, offering better strength and durability compared to the older porcelain versions.

- Protective Coatings: These help shield DIN rails from corrosion, extending their lifespan.

- International Standards:

- IEC 60715: Ensures safety and compatibility globally.

- EN 50022: Defines specifications for universal use.

By adhering to these standards, DIN rails remain reliable, safe, and efficient across various environments.

Conclusion

DIN rails are essential for organizing and securing electrical components in various applications. Their versatility makes them suitable for diverse industries, from automation to renewable energy. Using standardized DIN rail sizes simplifies installation and maintenance across different systems, enhancing both efficiency and safety.

Familiarity with DIN rail types and standards is crucial for professionals involved in electrical installations. By understanding the different types of DIN rails and their specific applications, professionals can make informed decisions that enhance the performance and reliability of their electrical setups.

Tel: +86-577-88671000

E-mail: ceo@tosun.com

Skype: tosunelectric

Wechat: +86-139 6881 9286

WhatsApp: +86-139 0587 7291

Address: Room No.1001 Wenzhou Fortune Center,Station Road, Wenzhou, China

REQUEST A QUOTE

WhatsApp us

: +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά