Leading Terminal Blocks Supplier

Discover our extensive range of high-quality terminal blocks for all your electrical distribution needs.

Home » Terminal Block Supplier

Discover our extensive range of high-quality terminal blocks for all your electrical distribution needs.

Home » Terminal Block Supplier

As an experienced terminal block suppliers and manufacturers, TOSUNlux insists and focuses on providing high quality, good performance rail terminal blocks to the world to meet customers' need.

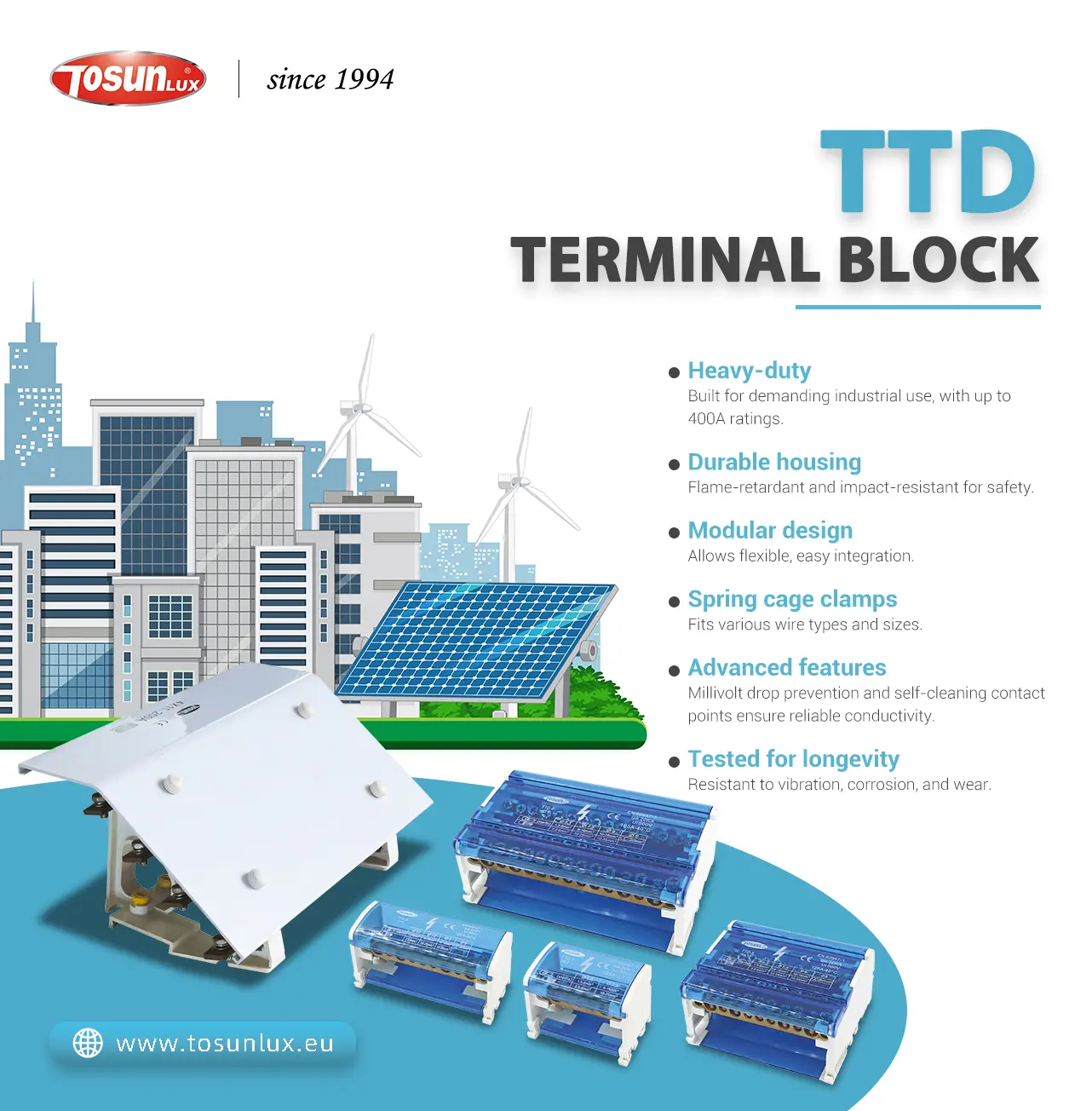

The TTD Terminal Block by TOSUNlux is a high-performing, heavy-duty terminal block designed for the most demanding industrial applications. With a flame-retardant, impact-resistant insulating housing, solid copper busbars, modular connectivity, and ratings up to 400A, TTD delivers safe, lasting electrical connections.

Its versatile, user-friendly spring cage clamp design accommodates a wide range of wire types and sizes. Unique advanced features like millivolt drop prevention and self-cleaning contact points ensure consistent conductivity and reduce maintenance needs. Rigorously tested for vibration, corrosion and longevity, TTD sets a new benchmark for terminal block performance and reliability.

TOSUNlux offers one-stop Terminal Blocks service for customers. Focused on the field of low voltage electrical for 30+ years.

Flame Retardant Protection

The specialized housing of TOSUNlux terminal blocks features flame retardant insulation designed to withstand extreme heat levels up to 950°C without emitting sparks or spreading fire. This protects connected components and prevents damage even when subjected to a high-amperage overload or short circuit.

Corrosion Resistance

All metal components of TOSUNlux terminal blocks receive a specialized anti-corrosion coating treatment to prevent rust and oxidation even when exposed to humidity, salt air, industrial chemicals, water splashes or other harsh conditions over long-term use.

Modular Flexibility

The modular design of TOSUNlux terminal blocks featuring detachable components enables customized configurations to suit unique control panel requirements. Sections interconnect in various combinations for optimized functionality.

Precision Engineering

Strict precision engineering and tolerance control during TOSUNlux automated production processes ensure durable terminal blocks that maintain consistent, reliable connectivity through millions of plug-in cycles.

Safety Certified

Compliant with IEC, UL, EN and other global safety standards, TOSUNlux rigorously tests terminal blocks to verify insulation, heat resistance, overload protection and other aspects vital for operator safety and proper performance in industrial and commercial systems.

Customization Capabilities

With experienced in-house engineering and customized production capabilities perfected through decades of specialization in terminal blocks, TOSUNlux can optimize terminal block designs to customer needs whether that involves durability, high-ampacity or density requirements dictated by the application.

About TOSUNlux

Established in 1994, TOSUNlux integrates R&D, manufacturing, and sales of terminal blocks and other electrical components used in industrial manufacturing, buildings, infrastructure, renewable energy, and agriculture.

Our state-of-the-art production lines and rigorous quality control ensure consistently high-grade products. TOSUNlux terminal blocks undergo extensive testing to verify protection against vibration, humidity, corrosion, heat, fire, and other hazards per CE, CB, TUV, IRAM and other standards.

Quality and Certification

Here are some frequently asked questions about TOSUNlux terminal blocks

Terminal blocks provide termination points to connect and distribute electrical wiring between components and systems. Their modular design simplifies complex wiring.

Many options exist like screwless, spring cage, removable, feed-through, ground, fuse, end-block, double-tier, etc. Materials range from plastic to ceramic or metal. Different sizes serve wiring gauges from 28-300MCM.

First insert stripped wire ends fully then tighten the screws to clamp connections securely. Align wires neatly to avoid dangerous shorts. Follow all local electrical codes.

If loose, corroded or damaged, terminal blocks should be replaced, not repaired. Attempting DIY fixes risks unsafe connections and violates manufacturer warranties.

Our global expertise in electrical distribution and ODM/OEM customization ensures terminal blocks with proven performance, safety certifications, quality assurance, and reliability even in harsh conditions.

One-Stop Solution To Electric

Explore our more product categories

TOSUNlux- a professional Terminal Blocks Manufacturer in China

For high-quality terminal blocks tailored to your application’s needs, contact the engineering experts at TOSUNlux today. Our global team stands ready to deliver advanced solutions and responsive support.

TOSUNlux terminal blocks enable simplified wiring and lasting performance in diverse sectors:

Flexible configurations suit complex automation systems

Flame-retardant blocks safely distribute power

Durability resists vibration in facilities and transit

Weatherproof housing protects controls outdoors

High amp blocks handle solar/wind generator currents

More Reliable Solution To Electric

We Help Your Business to Connect and Grow on Large Scale

TOSUNlux has its own design team with a 5-people in-house design team, which provides 4-5 new series of products every year for our clients.

Choosing the right terminal block connector and keeping connections clean are vital for safety and longevity in electrical systems. This blog covers key selection criteria and upkeep tips for terminal blocks.

Once installed, build scheduled inspection and maintenance into safety procedures. Watch for:

Replace damaged terminal blocks immediately. Attempted fixes risk unsafe connections violating safety certifications. Reputable terminal block suppliers like TOSUNlux offer reasonably priced replacement components with quick lead times, detailed wiring instructions, and responsive customer support to minimize downtime.

Selecting quality DIN rail terminal blocks matched to the application and establishing maintenance practices that catch issues early on helps sustain safe, reliable network operation over decades not just years. Partnering with an experienced terminal block supplier like TOSUNlux brings global expertise to your local electrical challenges.

Share this Blog

Tel: +86-577-88671000

E-mail: ceo@tosun.com

Skype: tosunelectric

Wechat: +86-139 6881 9286

WhatsApp: +86-139 0587 7291

Address: Room No.1001 Wenzhou Fortune Center,Station Road, Wenzhou, China

WhatsApp us