What Should Do if Your Circuit Breakers Keeps Tripping?

21st Nov 2024

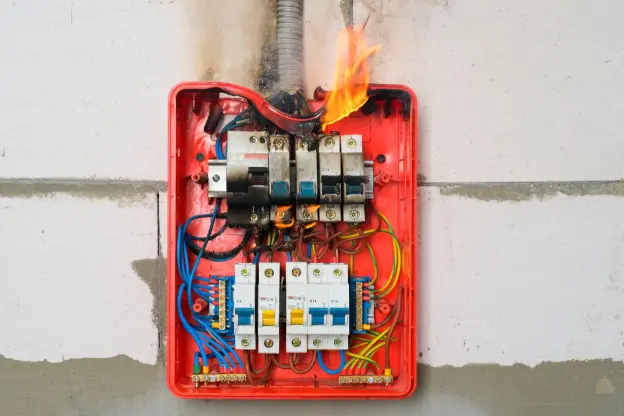

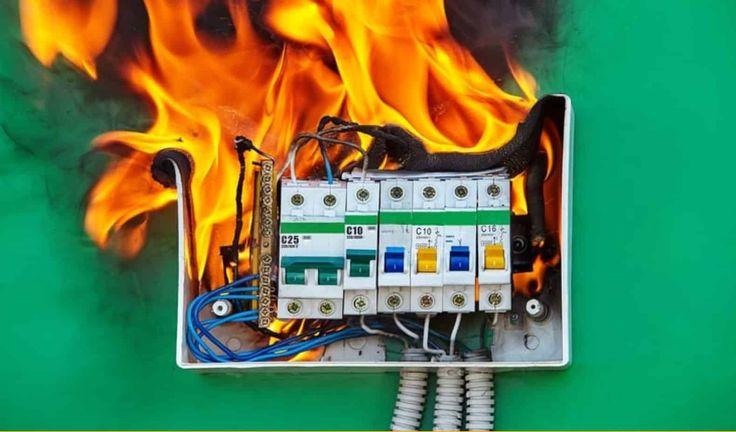

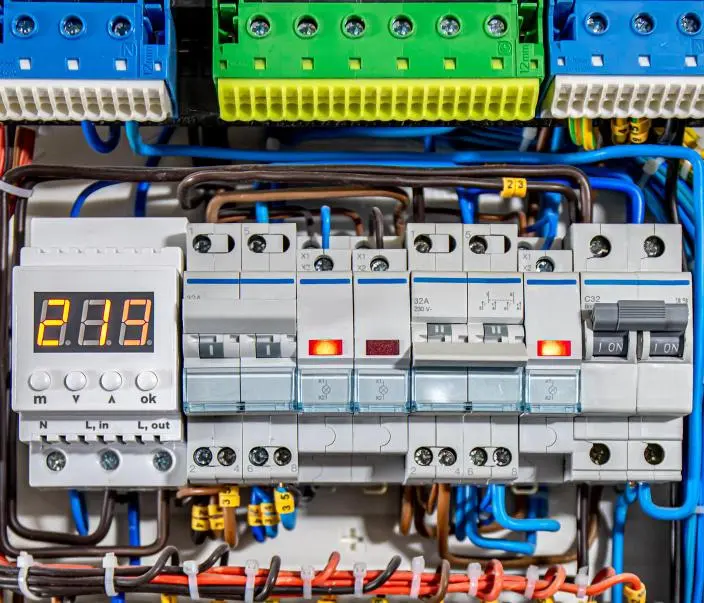

If your circuit breaker keeps tripping, it can be frustrating and confusing. But don’t worry! We’ll help you understand what’s happening and what to do when the breaker keeps tripping. Understanding Circuit Breaker Tripping Why does a circuit breaker trip? A circuit breaker trips or shuts off to protect your home. It’s like a safety switch that stops power when something is wrong. The breaker might trip because the circuit has too much load, there’s a short circuit, or something is grounded incorrectly. Overload: If too many devices are on one circuit, the breaker shuts off. This stops wires from overheating. Short Circuit: A short circuit occurs when a hot wire comes into contact with a neutral wire. This can cause sparks or heat, making the breaker shut off. Ground Fault: When a hot wire touches the ground wire or metal, it causes a surge. Breakers trip to keep you safe from shocks or fires. What to Do When Your Circuit Breaker Keeps Tripping When a circuit breaker trips, here’s what you should do to fix it: Turn Off and Unplug Devices Begin by switching off all devices connected to the affected circuit. Unplug them to reduce the load. This helps you determine if the issue is from an overloaded circuit or an appliance. Reset the Circuit Breaker Locate your breaker panel and find the tripped breaker. Move it fully to the “off” position, then flip it back to “on.” This should restore power, but if the breaker trips again immediately, the problem is likely […]

Read More : +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά