How to Connect Wire to Circuit Breaker: 10 Steps

12th Feb 2025

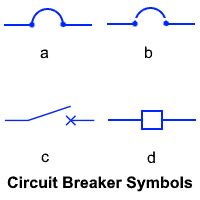

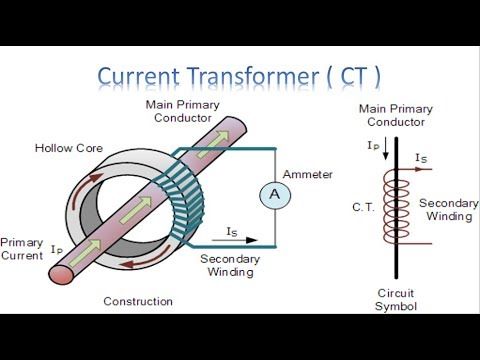

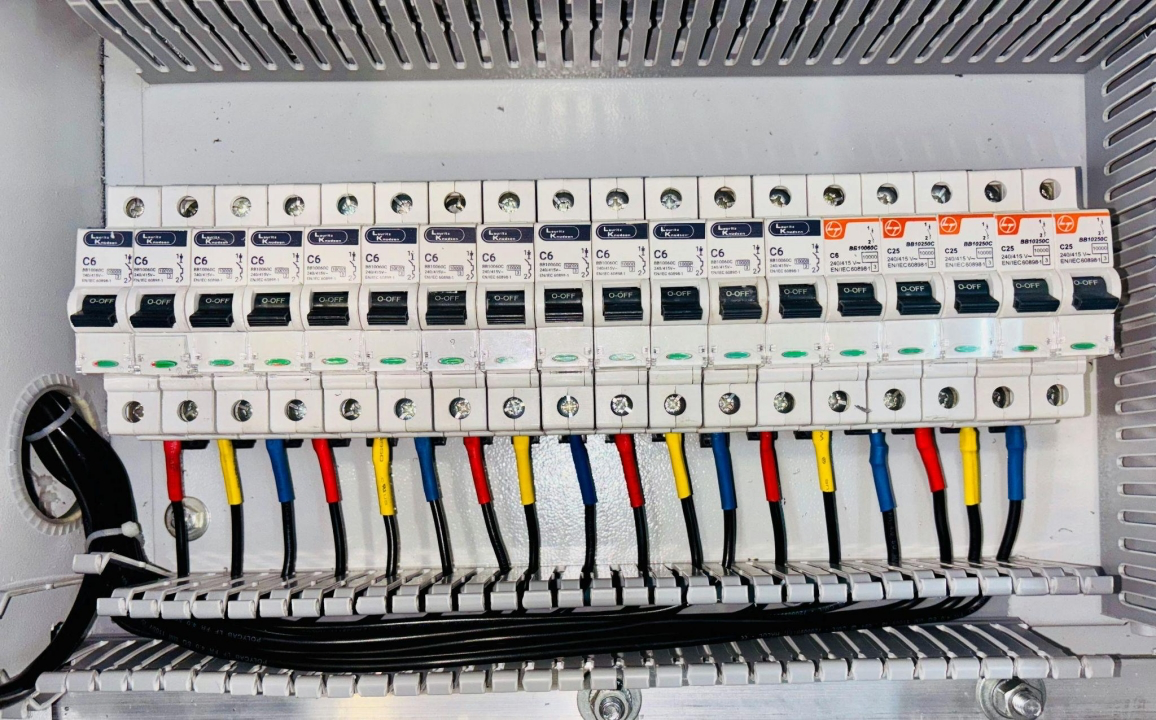

Connecting a wire to a circuit breaker requires careful handling to ensure safety and proper electrical function. The process involves selecting the right breaker, preparing the wires, and securing them into the breaker panel correctly. Whether you’re installing a 20-amp breaker, setting up a 240V circuit breaker, or replacing an old one, following the correct steps is crucial for preventing electrical hazards. This guide will walk you through the 10 essential steps to safely complete a circuit breaker connection while adhering to electrical codes. Understanding Circuit Breaker Connection Basics Before diving into the installation, it’s essential to understand how a circuit breaker panel wiring system works. Circuit breakers control the flow of electricity in a circuit and trip when an overload or short circuit occurs. A single-pole breaker (120V) connects to one hot wire, while a double-pole breaker (240V) connects to two hot wires. The neutral wire (white) returns current to the panel, and the ground wire (green/bare copper) provides a safety path for excess electricity. Having this basic knowledge will make it easier to follow the installation steps. Tools & Materials Needed Before starting, gather these tools and materials: ✔ Circuit breaker (correct amperage, e.g., 20A, 30A, or 50A)✔ Screwdrivers (flat-head and Phillips)✔ Wire strippers✔ Needle-nose pliers✔ Voltage tester✔ Electrical tape✔ Wire nuts (if splicing wires)✔ Correct gauge wire (12 AWG for a 20-amp breaker installation, 10 AWG for a 30A breaker, and 6 AWG for a 50A breaker) Once you have these tools ready, you can move on to the actual wiring process. […]

Read More : +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά