The Comprehensive Guide to Changeover Switch

22nd Aug 2023

Dive into the world of changeover switches, the silent guardians of power supply continuity. From their diverse types and critical applications to key selection considerations.

Read More

Dive into the world of changeover switches, the silent guardians of power supply continuity. From their diverse types and critical applications to key selection considerations.

Read More

Discover their ingenious design, applications in various industries, and the advantages that make them indispensable.

Read More

Take a deep dive into the world of pedal switches, the foot-operated control wonders. From their diverse functionality and types to real-world applications, explore how pedal switches are enhancing industries.

Read More

Control transformers are essential electrical devices used to provide reliable and stable voltage regulation for control circuits in various industrial and commercial applications. They play a critical role in maintaining proper voltage levels to ensure the safe and efficient operation of control systems. The Ultimate Guide to Control Transformers provides comprehensive insights into their function, types, and applications, showcasing their significance in electrical control circuits. Function of Control Transformer Control transformers are specifically designed to step down voltage levels in control circuits, providing a reduced and stable output voltage that is suitable for powering control devices like relays, timers, contactors, and solenoids. They are commonly used to convert higher voltage levels, typically found in power distribution systems, into lower and safer voltage levels that can be utilized by control devices without risking damage or malfunction. Types of Control Transformers Single-Phase Control Transformer: Single-phase control transformers are commonly used in applications where the control circuit operates on a single-phase supply. They are ideal for small to medium-sized control systems and are widely used in residential, commercial, and industrial settings. Three-Phase Control Transformer: Three-phase control transformers are used in applications that require a three-phase power supply for control circuits. They are widely used in larger industrial control systems that require higher power capacity and where three-phase power is readily available. Step-Up Control Transformer: Step-up control transformers are designed to increase the output voltage from the input voltage. They are used in applications with a higher voltage for control devices and circuits. Step-Down Control Transformer: Step-down control transformers, […]

Read More

Microwave sensors, also known as radar sensors, are electronic devices that use microwave radiation to detect motion, presence, or distance. They are widely used in various applications, from automatic doors and security systems to industrial automation and traffic management. This complete guide to microwave sensors provides comprehensive insights into their working principle, applications, and advantages, showcasing their significance in modern technology and everyday life. Working Principle of Microwave Sensors Microwave sensors operate on the principle of the Doppler effect or radar technology. They emit continuous microwave signals, which bounce off objects in their detection area and return to the sensor. When there is no motion, the reflected signals have the same frequency as the emitted signals. However, when an object moves within the sensor’s detection range, the frequency of the reflected signals changes due to the Doppler effect. The sensor detects this frequency shift, indicating the presence and speed of the moving object. Types of Microwave Sensors Microwave Motion Sensors: These sensors detect motion by analyzing changes in the reflected microwave signals. Proximity Sensors: Proximity sensors use microwave radiation to detect the presence of objects within a specified range. Speed Sensors: Speed sensors use microwave technology to measure the speed of moving objects, such as vehicles on roads or trains on tracks. Distance Measurement Sensors: These sensors use microwave signals to measure the distance between the sensor and an object. Applications of Microwave Sensors Automatic Doors: Microwave sensors are widely used in automatic doors found in shopping malls, airports, and commercial buildings. The sensors detect […]

Read More

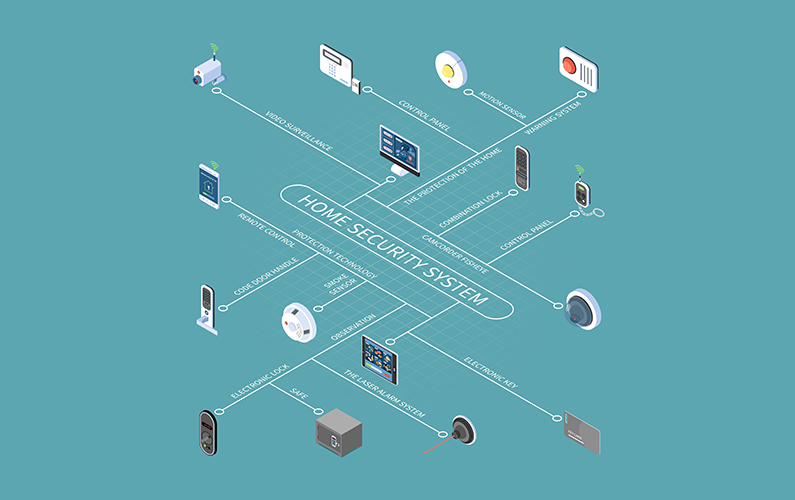

What is infrared motion sensor Infrared motion sensors, also known as passive infrared (PIR) sensors, are electronic devices that detect infrared radiation emitted by objects in their field of view. These sensors are widely used in various applications, from security systems and automatic lighting to energy-saving devices and smart home automation. The ultimate guide to infrared motion sensors provides comprehensive insights into their technology, applications, and advantages, showcasing their significance in modern technology and everyday life. Working Principle of Infrared Motion Sensor Infrared motion sensors work based on detecting changes in infrared radiation emitted by warm objects in their surroundings. The sensors consist of one or more pyroelectric sensors that detect infrared radiation. When a warm object moves within the sensor’s field of view, it causes a change in the amount of infrared radiation detected by the sensor. This change triggers the sensor to send a signal, indicating motion, which can be used to trigger various actions or alarms. Types of Infrared Motion Sensors Passive Infrared (PIR) Sensors: PIR sensors are the most common infrared motion sensors. They detect changes in infrared radiation but do not emit any radiation themselves. PIR sensors are widely used in security systems, automatic lighting, and occupancy detection. Active Infrared (AIR) Sensors: AIR sensors emit and detect infrared radiation. They are commonly used in distance measurement, obstacle detection, and object counting applications. Dual Technology Sensors: Dual technology sensors combine infrared technology with other sensing technologies, such as microwave or ultrasonic sensors. The combination of these technologies improves accuracy and reduces […]

Read More

LED indicators, also known as LED lights or simply LEDs (Light Emitting Diodes), are small semiconductor devices that emit light when an electric current passes through them. These versatile and energy-efficient components find extensive use across various industries and applications, serving as visual indicators, status indicators, and warning lights. This complete guide to LED indicators aims to shed light on their functionality, characteristics, and diverse applications in modern technology and everyday life. The functionality of LED Indicators LED indicators work on the principle of electroluminescence. When a forward voltage is applied to the LED’s semiconductor junction, electrons and holes recombine, releasing energy in the form of light. The emitted light’s color depends on the semiconductor material used, with common colors being red, green, blue, yellow, and white. LED indicators are available in various sizes, shapes, and configurations, ranging from small surface-mount LEDs to larger through-hole LEDs. The light emitted by LEDs is unidirectional, which makes them ideal for applications requiring focused illumination and sharp contrast. Characteristics of LED Indicators Energy Efficiency: LED indicators are highly energy-efficient, converting a significant portion of the electrical energy into light without generating excess heat. This efficiency contributes to reduced power consumption and longer operational life compared to traditional incandescent or fluorescent indicators. Longevity: LEDs have a much longer operational life compared to conventional light sources. Their solid-state design allows them to withstand shock, vibration, and frequent switching without compromising performance, making them ideal for applications where reliability is crucial. Instant On/Off: LED indicators achieve full brightness almost instantaneously when powered on and […]

Read More

What is Indicator Type Digital Meter An indicator-type digital meter, often simply referred to as an indicator meter, is a specialized digital measuring instrument used to display and present specific data or measurements in a clear and user-friendly manner. Unlike traditional analog meters, indicator-type digital meters use digital displays, such as LED (Light Emitting Diode) or LCD (Liquid Crystal Display) screens, to show numerical values or graphical representations of the measured quantities. These meters find extensive use across various industries and applications due to their accuracy, reliability, and ease of reading. The Importance of Indicator Type Digital Meter Accuracy and Precision One of the primary reasons for the widespread adoption of indicator-type digital meters is their high level of accuracy and precision. These meters can provide readings with decimal points, allowing for finer measurements and reducing the chances of human error during interpretation. In critical applications like scientific research, industrial processes, or medical diagnostics, precision is of utmost importance, making these meters indispensable tools. Instantaneous Readings Indicator-type digital meters offer instantaneous readings, displaying the measured values in real time. This real-time data retrieval is invaluable in applications where prompt decisions are necessary, such as in control systems, process monitoring, or safety-critical situations. Operators can quickly assess the data and respond accordingly, enhancing efficiency and ensuring optimal performance. Easy-to-Read Displays The digital display of indicator meters is designed for user-friendliness and readability. The numerical values are clear and legible, eliminating the need for interpreting needle positions or analog scales, which can be cumbersome and prone to […]

Read More

Explore features, certifications, and brand reputation to ensure optimal equipment performance.

Read More

timer relays play a crucial role in automation and control systems, offering accurate time-delay functionality that is essential in various industrial applications. Tosunlux, a leading manufacturer of electrical and electronic components, has emerged as a pioneer in providing innovative timer relay solutions that cater to diverse industrial needs. This comprehensive guide explores the remarkable features and applications of Tosunlux’s timer relays, highlighting their exceptional contributions to the field of industrial automation. Overview of timer relay timer relays are devices used to introduce a time delay between the input signal and the output response. These relays enable machines and systems to carry out specific actions after a set time duration, thereby optimizing process efficiency and ensuring safety. Tosunlux offers a wide range of timer relays designed with precision and cutting-edge technology tailored to meet the specific requirements of industries across the globe. Unique Features of timer relay Precision and Accuracy: timer relays boast exceptional precision and accuracy, guaranteeing reliable and consistent time delay operations. This characteristic is critical in industrial applications where synchronization and time-critical actions are paramount. Adjustable Time Delay timer relays allow users to fine-tune the time delay settings, providing flexibility and adaptability to various operational scenarios. This versatility makes them suitable for a diverse range of applications, from simple time-based processes to complex automation tasks. Compact Design Tosunlux emphasizes compactness in their timer relay designs, ensuring easy integration into control panels and switchgear. This space-saving feature enables efficient use of limited enclosure space, a crucial aspect in modern industrial setups. Wide Voltage Range timer relays are designed to function seamlessly across a […]

Read MoreTel: +86-577-88671000

E-mail: ceo@tosun.com

Skype: tosunelectric

Wechat: +86-139 6881 9286

WhatsApp: +86-139 0587 7291

Address: Room No.1001 Wenzhou Fortune Center,Station Road, Wenzhou, China

WhatsApp us