The Advantages of Thermal Relay Protection

04th Apr 2025

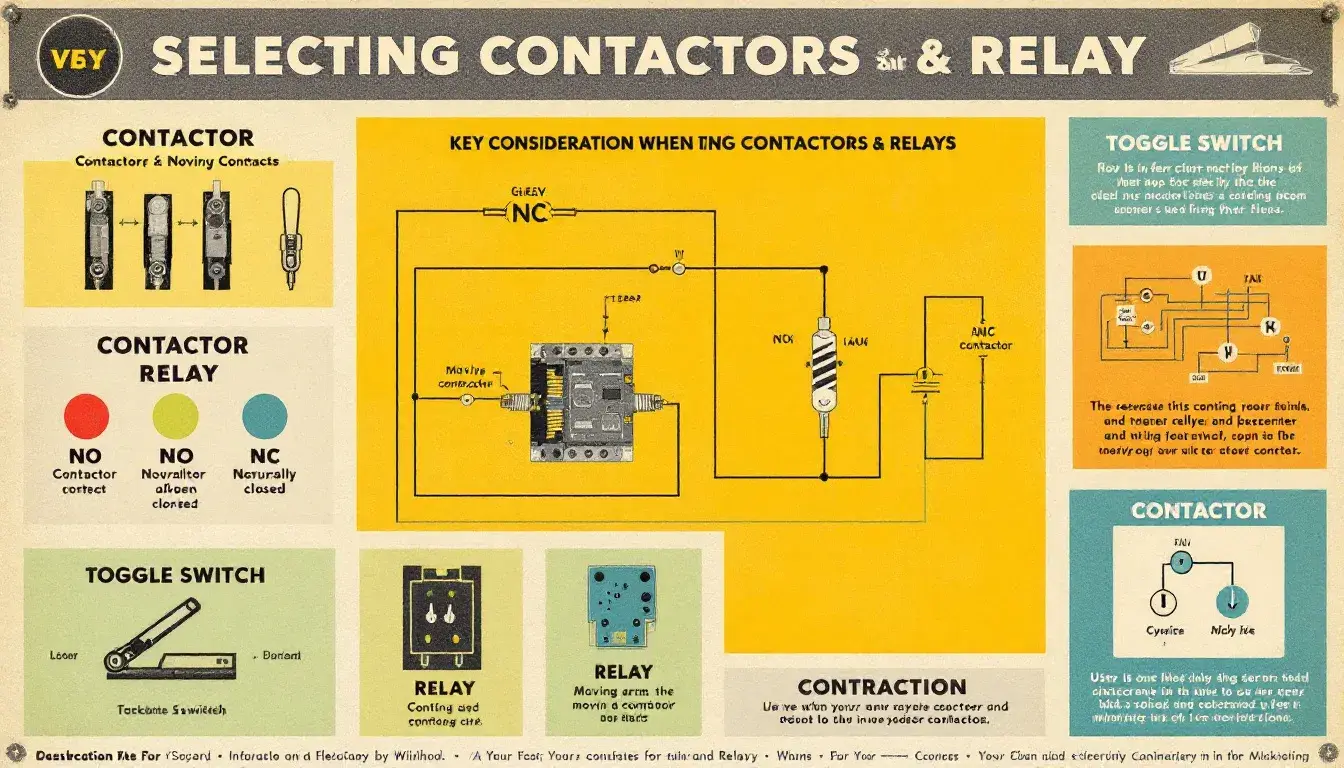

Thermal relay protection is essential for safeguarding electrical circuits from overheating and damage. It works by monitoring the heat in circuits and interrupting the power supply if temperatures get too high, preventing failures and extending equipment life. In this article, we will explore what thermal relay protection is, how it works, and its benefits and drawbacks. What is Thermal Relay Protection? Thermal relay protection prevents overheating and short circuits in manual control electrical circuits. A thermal overload relay monitors heat within an electrical circuit. If a motor draws excessive current, leading to potential damage, the relay trips to interrupt the circuit and prevent further harm. Thermal overload relays protect motors from electrical overloads by detecting heat during operation. If the temperature exceeds a safe threshold, the thermal overload relay responds, and the relay trips to cut the power supply, preventing motor failure and extending equipment life. Understanding how thermal overload relay work is essential for effective motor protection. For instance, the Chint Thermal Overload Relay prevents fires and electrical problems while protecting cable systems during excessive current situations. These relays are crucial in preventing permanent damage from overheating, making them indispensable for motor protection, system reliability, and as an overload protection device. Auto Reset vs Manual Reset on Thermal Overload Relays Feature Auto-Reset Thermal Overload Relays Manual Reset Thermal Overload Relays Operation Automatically restarts the motor after cooling. Requires external action to restart the motor after a trip. Safety May pose risks due to unintended motor restarts. Safer as it ensures investigation and resolution of […]

Read More : +86-139 0587 7291

: +86-139 0587 7291 English

English Español

Español Русский

Русский Français

Français العربية

العربية Português do Brasil

Português do Brasil Українська

Українська Türkçe

Türkçe Polski

Polski Nederlands

Nederlands Italiano

Italiano Bahasa Indonesia

Bahasa Indonesia हिन्दी

हिन्दी اردو

اردو አማርኛ

አማርኛ Հայերեն

Հայերեն ไทย

ไทย Монгол

Монгол فارسی

فارسی Shqip

Shqip Ελληνικά

Ελληνικά